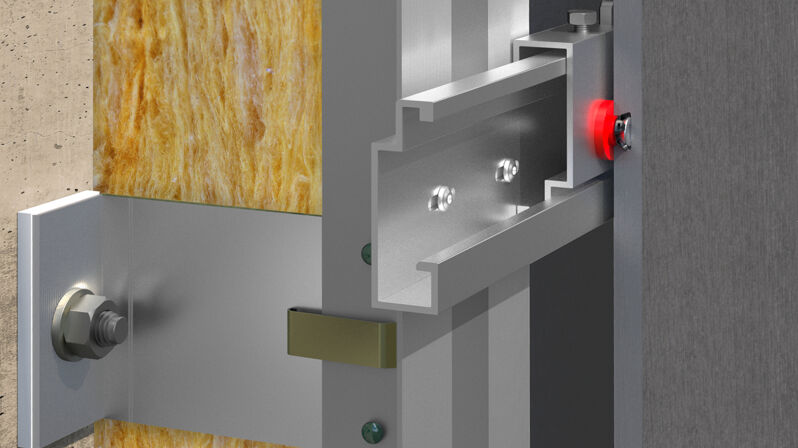

| ETA-approval | |

| Min. panel thickness | 12 mm |

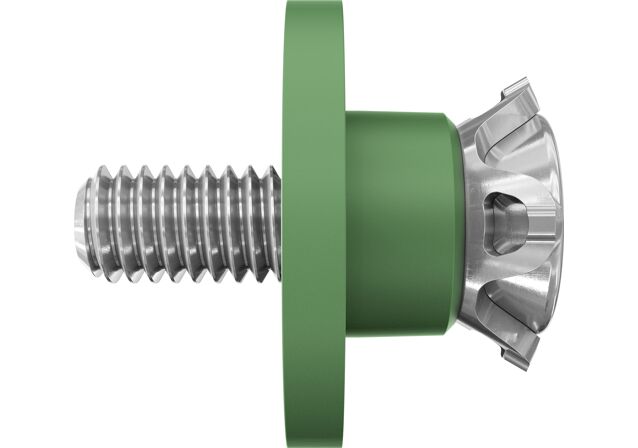

| Embedment depth | 10 mm |

| Total length ( l ) | 21,5 mm |

| Installed anchor length | 12,5 mm |

| Remaining thread length | 9 mm |

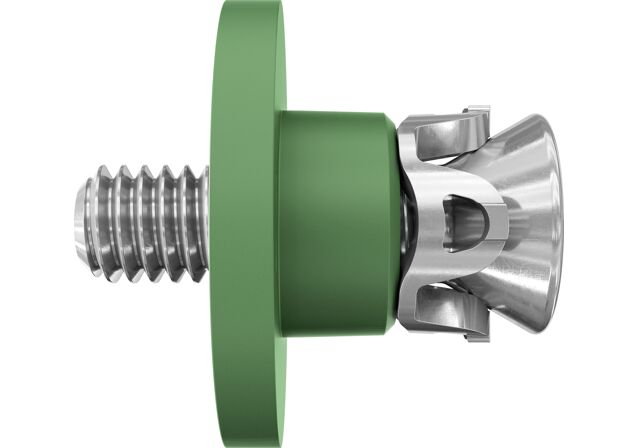

| Thread ( M ) | M6 |

| Cylindrical diameter | 11 mm |

| Undercutdiameter | 13,5 mm |

| Color washer | green |

| Seismic-Approval | C1 / C2 |

| System | — |

| Amount | 250 St. |

| GTIN (EAN-Code) | 4048962217728 |