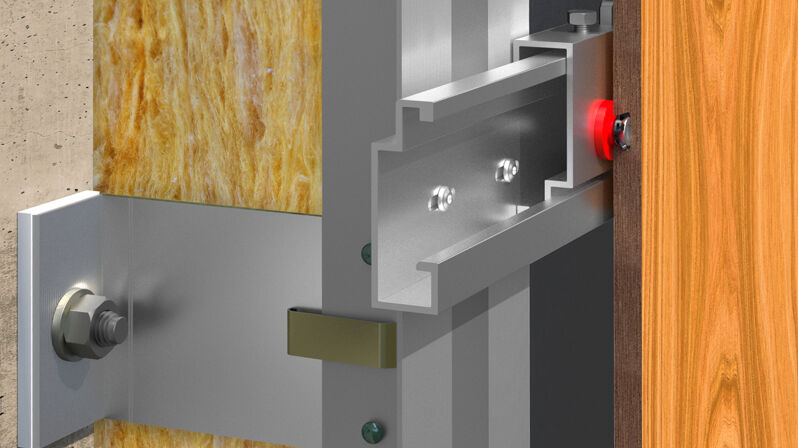

| ETA-approval | |

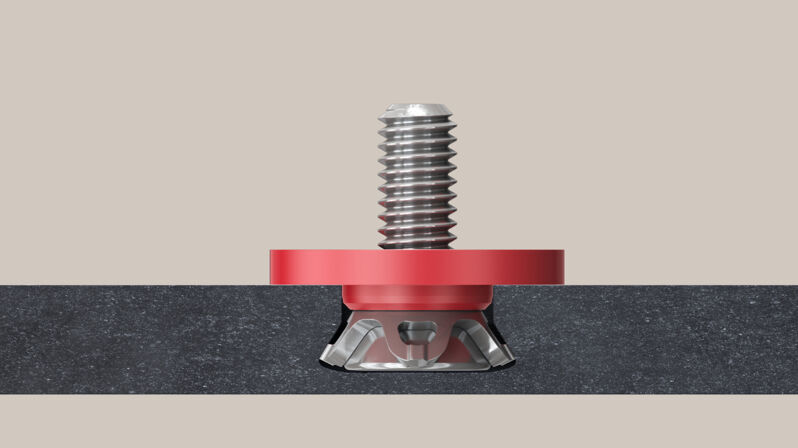

| Min. panel thickness | 8 mm |

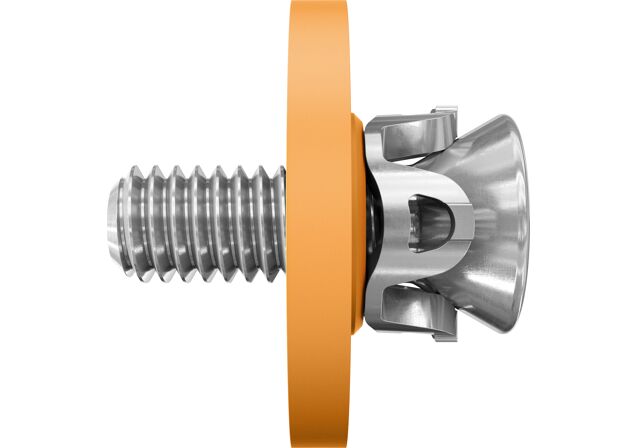

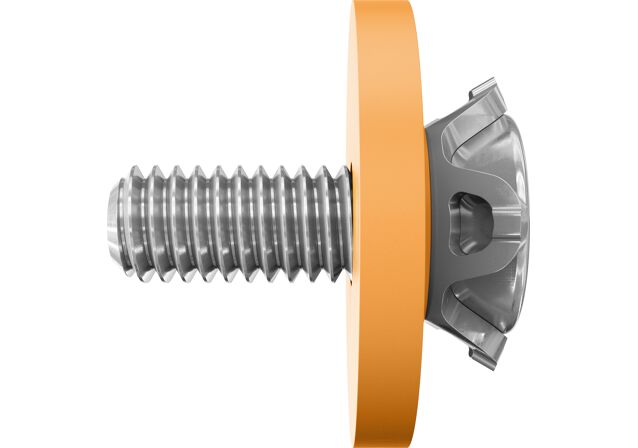

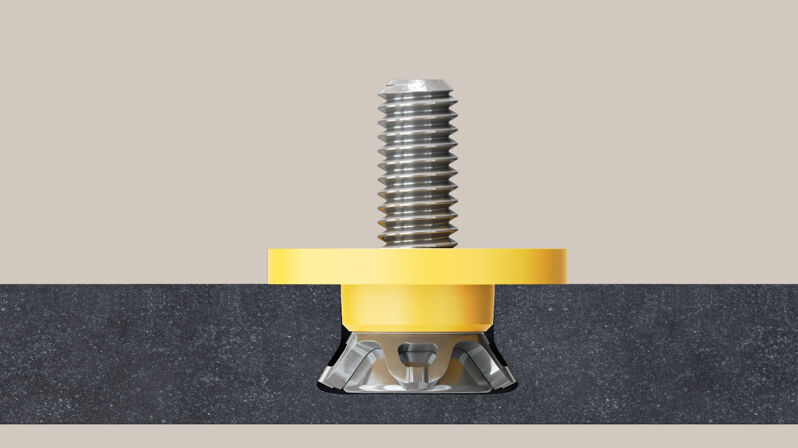

| Embedment depth | 5 mm |

| Total length ( l ) | 18,5 mm |

| Installed anchor length | 7,5 mm |

| Remaining thread length | 11 mm |

| Thread ( M ) | M6 |

| Cylindrical diameter | 11 mm |

| Undercutdiameter | 13,5 mm |

| Color washer | orange |

| Seismic-Approval | C1 / C2 |

| System | — |

| Amount | 250 St. |

| GTIN (EAN-Code) | 4048962362053 |